Bridge

| Bridge | |||||||

|---|---|---|---|---|---|---|---|

| Type | Engineering | ||||||

| Category | Build | ||||||

| Description | Teams will design and build a Bridge (Structure) meeting requirement specified in these rules to achieve the highest structural efficiency. | ||||||

| Event Information | |||||||

| Participants | 2 | ||||||

| Approx. Time | 6 minutes | ||||||

| Impound | No | ||||||

| Allowed Resources |

| ||||||

| Rotates | Yes (with Towers and Boomilever) | ||||||

| Eye Protection | B | ||||||

| Latest Appearance | 2023 | ||||||

| Forum Threads | |||||||

| |||||||

| Additional Resources | |||||||

| Image Gallery | Link | ||||||

| Division B Results | |||||||

| |||||||

| Division C Results | |||||||

| |||||||

Bridge (previously known as Bridge Building) is a build event run being run in both divisions in the 2023 season. The objective of the event is to build a bridge which is very lightweight and capable of holding a designated weight for maximum efficiency. The bridge must meet specific construction parameters, including dimension requirements. These requirements are expected to be characterized in a Design Log, which all teams must submit along with their bridge at the time of competition.

The event consists of two main parts: check-in and testing. In check-in, teams will present their devices for inspection. If the team's inspection passes, the event supervisors will test the team's device against the common testing apparatus. Team members will load sand into a bucket below their bridge, and stop loading sand once the device fails or time (6 minutes) expires. The maximum load supported will be recorded as the team's score for the testing portion of the event.

The event replaced Boomilever, another balsa-focused event, to be run again in the 2022 season, having last been run in 2016. The event is sponsored by SkyCiv for the 2022 season.

Overview

Bridge Building is a construction event that involves building and testing a bridge. The bridge must span a horizontal opening of 35.0 cm (Division B) or 45.0 cm (Division C), marked by two clear span lines. In 2016, the bridge must be designed to sit on a test support set at 5 cm high in one of the ends, and the bridge must not exceed 2.0 cm on the other end when it crosses the clear span line. The bridge may be constructed using only wood and bonded only by glue.

A hole will be located in the center of the test base. A loading block will be placed above the hole, and a chain will hang from it and hold a bucket that will be loaded with sand. Both the supporting block and the loading block have dimension 5.0 cm * 5.0 cm * approximately 2.0 cm.

All appropriate descriptions of the aforementioned terms and size specifications can be found in the rules manual.

Tips for Getting Started

- Start by researching designs and plans for the most stable and lightweight bridge possible.

- The next step for construction is to draw your plan out. Draw it the exact size you want your bridge, place on cardboard or foam, and cover it with wax paper; you will need to use this to aid in construction.

- You will need to buy materials with which to construct your bridge. The rules state the bridge must be constructed only of wood joined by glue. Research the strengths and weaknesses of different woods and glues. Remember, ultimately you want the lightest but strongest bridge.

- Try to be exact when cutting the pieces. You can use band saw and sand the ends to the correct angle.

Design

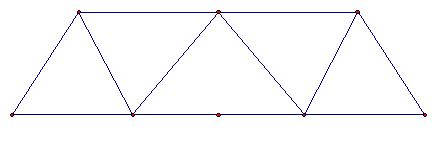

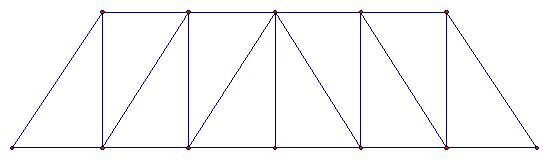

There are a countless number of designs for a bridge. Bridges are designed using trusses. Many different truss structures exist. The three most common are Warren, Pratt, and Howe.

Warren Truss

The Warren truss features truss members that form equilateral triangles. Each diagonal is subject to the same load, with every other member alternating between tension and compression.

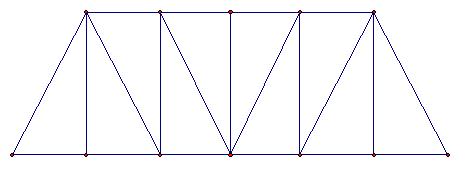

Pratt Truss

The Pratt Truss contains right triangles in its design. The slants face the center of the bridge.

Howe Truss

The Howe Truss is similar to the Pratt Truss, except the slants face away from the center of the bridge. The difference with the Howe Truss is that the slants become compression members and the vertical members become tension members.

There is no preferred truss design. When designed and built correctly, any of these truss designs can work well. Other, less common, truss designs can be as or more effective depending on how they are used.

Before building any bridge, it is critical to design the truss and calculate loads with a truss analysis program. Many such programs exist. The recently released open source program by Prof. Ivan Markov from RPI is extremely user friendly and can be helpful in the design explorations. The other is from John Hopkins university, and can be found in the link below. Other, more featured programs, include MDSolids and Dr. Frame. The design of one face of the bridge should be constructed in the program. Then, the load can be applied to the center of the bridge, and the stress in each truss member can be calculated.

This information is extremely important when designing the bridge. Generally, it is better to use stronger or thicker wood in areas with greater stresses.

Sides angled in a bit might help your design, but it is not the same for everyone. Vertical sides give you no room for error, no latitude for a loading force that is not perfectly vertical (i.e. any bucket swing, or any difference in the height of the two sides, any error in sides being vertical, i.e. leaning slightly outward). Sides angled in do give you a margin for error/bucket swing, and b) give you inherent stability. Yes, looking at the legs, this does introduce “new”/additional forces, compared to vertical; the compression load goes up slightly (compared to vertical), but that additional load (when you work out the vectors) is a function of the cosine of the angle. When you look at a table of cosine values, you will see that in the first few degrees, it is a VERY small factor. It does mean the base of the legs will be pushing out- that you have to put a piece between the ends of the legs on each side, that will be under very light tension loading (less than ½ kg). (Courtesy of Balsa Man)

Compression and Tension

Compression and Tension are the two primary forces acting upon your bridge. An easy way to think of compression and tension is the direction in the which the force is being applied.

Compression

Stand across from another person. Put your hands on each others shoulders, and lean in. You are experiencing compression.

Another way to look at it is if you sat on top of a table. The legs of the table would be under compression.

When wood is under compression, it tends to buckle. You generally want slightly denser wood for areas of compression, depending upon the amount of compressive force.

Tension

Stand across from another person. Hold hands and lean back. Your arms feel as if they are being stretched apart. This is tension.

Another way to think about it is if you had a pencil and you held it with both hands at opposite ends, and pulled at it from each side.

When wood is under tension, it tends to snap. You generally want a flexible piece of wood for areas of tension.

Building

Prior to the competition, teams will construct their bridge. Bridges are not hard to build, but do take practice.

The more bridges you build and break, the more you will learn, and thus the more improvement you can make. It is important that you test as much as possible. Every broken bridge will help you improve with your next bridge. One helpful testing mechanism is a "safety tower." The initial failure of one part of the bridge will subsequently cause failure of other parts, which is secondary damage and did not contribute to the failure of the bridge. A rig that stops the loading block from falling once the bridge has broken will allow the bridge to remain intact after the initial failure, without any secondary damage. This allows the point of failure to be identified. Filming, and reviewing film can be very helpful in pinpointing your mode(s) of failure. Many cameras on phones today capture anywhere from 120-240fps slow-motion video, so if possible, make sure to film, and look back at every bridge you test, because you may see something you missed in real-time.

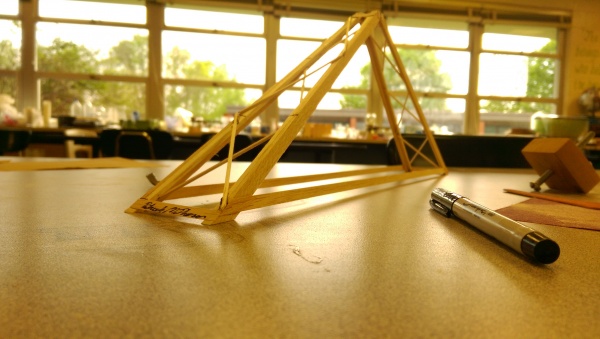

The best way to build a bridge is as two 2-dimensional faces. A template can be drawn out on poster board. Attach wax paper over the template to ensure that the bridge is not glued to the template. Use pins to help keep pieces in place. (Do not puncture the members of the bridge with the pins, only place them next to the bride to hold it in place)

An alternative method is to use cellophane tape over your template, so the superglue will not bond the bridge to your workspace. The bridge's individual pieces can then be scotch-taped to the template if they need be secured.

After both faces of the bridge are constructed, they must be put together. A jig that holds the sides parallel is useful in this situation.

Lateral bracing refers to bracing between the two sides of the bridge. Generally the top of the bridge is in compression, and the bottom of the bridge is in tension. The bridge pictured has lateral bracing on the top, to prevent those larger members from buckling into failure, the bottom members are not tied together, because they are being pulled on while the bridge is being loaded. However, it must be noted that lateral bracing is very important, and you can always remove it as you refine your design.

The best bridges are built with a very high attention to detail, you can always improve how well your bridge is constructed, and making sure all of the joints are glued well, and there are not obviously defective pieces is very important both when refining your design, and testing at the competition. It is key to make sure you improve upon your designs' failures. Ideally, you should test your design, fix what broke, and repeat as many times as you are able to throughout the season. It can be very surprising how much of a difference it makes to pay attention to the details of your bridge.

Construction Materials

Bridges can be made out of any type of wood except those excluded in the rules, such as particleboard, plywood, bamboo, , etc. Balsa has the highest strength-to-weight ratio of any commonly available wood, and is readily available in many sizes at your local hobby shop.

When selecting balsa, it is important to ensure that all pieces used are of appropriate density. This can be found by weighing the wood with a pocket scale. One should also ensure there are no identifiable defects in the wood grain, as this may cause premature failure. You can buy balsa wood in sheets and cut out your own sticks or buy pre-cut sticks. If you choose to buy in sheets, look out for the grain of the wood. There are 3 kinds of grain: A, B, and C. A grain is more flexible and is best for tension members. C grain is more stiff and good for compression. B grain is a combination of the two.

Basswood is also commonly used in bridges. It is stronger than balsa, but also much heavier. It can be very effective when used strategically.

Balsa or Bass?

Different bridges use different wood. It's completely up to you whether to use balsa wood or basswood when building your bridge. There are pros and cons to both:

Balsa pros: Lightweight, cheaper, easier to cut/sand, changes mass in different humidity.

Balsa cons: Weaker, inconsistent density.

Bass pros: Stronger, holds together better at joints, doesn't crush, same strength throughout stick, bends more.

Bass cons: Heavier, more expensive.

The kind of wood you use is completely up to you. You can build strong bridges with either kind of wood. Depending on your design, you might want one wood over the other. If you have many pieces in your design, you might consider balsa, as it is lightweight. But if you have few pieces but still want a strong bridge, bass is the way to go. It's best if you experiment with both kinds of wood and see what you prefer.

If you find that there is a joint that is constantly the fault of your bridge, you might want to change that piece to basswood. If you find that some pieces never break and barely receive any compression/tension, then you might want to consider changing it to balsawood to reduce weight.

Glue

The wood may be bonded by any type of glue. This includes wood glues, cements such as Duco or Ambroid, Gorilla, and CA. CA works very well for bonding bridges. It is available in various viscosities. Thin CA will seep into the wood at the joints, thereby strengthening the overall joint. A medium viscosity seems more like a gel, it also seeps into the cracks, and when completely dry, is fairly stronger than thin CA. However, medium viscosity takes a few minutes longer to dry than the thin. It also cures in seconds, facilitating the construction of the bridge. Wood glue such as Gorilla Glue are also strong in bonding any type of wood, although they are heavy. They also take much longer to dry. Glues like Gorilla Glue need clamps to hold the device together, because the glue expands a lot over time. When using any type of glue, it is important to use the appropriate amount. A little glue can go a long way, and using too much glue is a very easy way to drastically increase the mass of a bridge.

Note that some joints are more important than others, so you may want to use more or less glue at your discretion. Glue weight is NOT negligible, so it is important to use the appropriate amount, which may take time to discover. Ideally you won't need to fill any gaps with your glue, but a nice combination of the thin and medium viscosity super-glues work well for many.

There are quite a few CA glues, which include Krazy Glue, Insta-Weld, Permatex, Zap-a-Gap, and many more. Most (if not all) can be found at a nearby hobby-shop, online, or just at your nearest department store.

Joints

There are various joints that you can use when building a bridge. There are 3 main kinds of joints: Lap joint, end/butt joint, and notched joint. However, it is not avoided to use a notched joint, because cutting a notch into such a small piece of balsa wood isn't usually worth the sacrifice in the strength of your members.

End/Butt Joint The end joint is the weakest joint. It's where you place the end of one stick against the side of another. This joint is bad for tension, because the two pieces will pull right apart. In the picture shown of the bridge above, you can see that the builder used butt/end joints. When using an end joint, it is important that you sand the end of your stick so that it makes a flush, "airtight" seal. If there is a small gap the glue must fill, the joint will be significantly weakened.

Lap Joint The lap joint is one of the strongest joints. You place the side of one stick on top of the side of another stick. This joint helps compression members to not bend. The lap joint's strength depends on the type of glue you are using. Lap joints have more surface area for the glue to work on than the end joint.

Gussets Sometimes you can't avoid using an end joint. However, you can make a gusset to make the joint as strong as a lap joint. A gusset is made by placing a thin piece of wood over the joint, thus covering the crack between the wood. You can make an even stronger joint if you place a gusset on both sides of the joint. By adding more gussets, this would increase the surface area of the glue, and it provides more stability. However, do not use too much glue, as it is only needed for a thin coat where to pieces meet. If used correctly gussets can be very useful in your design.

Modifications for Uneven Surfaces

For the 2016 season, teams will be required to build a bridge that can support weight on an uneven surface; in this case, the surface is defined as one side being on the testing table and the other being on a 5 cm tall support block.

The best strategy for this modification is to build trusses that are either triangular or irregular trapezoidal in shape such that one leg extends 5 cm vertically below the other. It is also important to ensure that the testing block can be supported parallel to the horizontal to avoid a vertical component of stress.

From a physics standpoint, it is best to avoid vertical components of stress at all costs in this event. Stress is defined as force per unit area, meaning that it is best to apply forces to the side of a structure with the most surface area. (However, note that you need to do so as close to the horizontal coordinate of the center of mass as possible for structural integrity, else torque will come into play and cause early failure.) Typically, the most surface area on a bridge will be on the horizontal axis, meaning that if a force is applied to that side, the stress will be smaller than at any other point on the bridge.

While adding weight at an angle will reduce the horizontal component of the force and thus the stress, a vertical component could very much imply disaster. First of all, the vertical surface area of bridges made for the event is much smaller than that on the horizontal surface, particularly on the axis that the force would be applied to. Most bridges will have vertical support on the other vertical axis (i.e. the sides perpendicular to those modified for the uneven surface) to protect against strain, but the other vertical side is not protected. This means that the stress will be larger than on the horizontal axis. Second, adding a vertical component will result in an unbalanced torque on the bridge. The torque will act on only one side of the bridge and cause unneeded strain on that side, which would imply early failure. Make sure that vertical components of force due to the attached weight does not impede your bridge's efficiency.

Testing

Before testing, the bridge must be weighed.

During testing, the bridge will be placed on the test base, so that it touches only within the bearing zone. The competitors will then assemble and place the loading block on or within the bridge, so long as it is above the standard minimum clearance. An s-hook will be used to suspend a chain from the loading block, and the chain will support a bucket that is approximately one inch off the floor.

Contestants will then load sand into the bridge until it fails or holds 15.000 kg. At that time, the bucket of sand will be weighed, and the structural efficiency determined.

Structural efficiency is found by dividing the mass held by the bridge by the mass of the bridge itself. Generally, these measurements will be in grams, although any units of mass may be used, provided they are the same.

If you are using a scale that measures in pounds (lbs) then the maximum load is 33 pounds. For instance, if your bridge weighs 10g and you hold 15 pounds, you would multiply 15 pounds by 454 to convert it to grams. This would get you 6810 grams. Then you would divide 6810 by 10g (the mass of your bridge) and your efficiency would be 681.0. Google will also convert measurements. For example, if you search for "33 pounds to kilograms" Google's calculator will tell you that it equals 14.9685482 kilograms.

Similar Events

There are events similar to this one, in which you build a wood structure that is light and stable. The physics of these are different, but the general concept is the same.

Links

- Garrett's Bridges 5 steps

- Glue Weight

- Specialized Balsa

- Online Tool for Calculating Forces in Truss and Frame Structures

- Bridge Designer

- RPI Online Truss Simulator

| Division B: Airjectory · Bridge Building | Division C: Game On · Hydrogeology |