Electric Vehicle

The scioly.org wiki is publically editable by all members of the community. It is to the best interest of all competitors and supervisors to avoid citing information on this page for the event Vehicle Design. |

| Electric Vehicle | ||||||

|---|---|---|---|---|---|---|

| Type | Engineering | |||||

| Category | Build | |||||

| Event Information | ||||||

| Latest Appearance | 2017 | |||||

| Forum Threads | ||||||

| ||||||

The goal of Electric Vehicle is to build and test a vehicle that can travel a given distance in the shortest amount of time while staying in a straight line. This event was run in 2008 and 2009, and returned again in the 2016 season.

Event Parameters

Construction Parameters

- Only the wheel base must fit in an area 30.0 cm by 60.0 cm.

- There must be a 1/4 inch dowel attached to the front of the vehicle. It must extend upwards up to at least 20.0cm as well as be within 1 cm of the ground. Nothing can be ahead of the dowel on the car except whatever is being used to attach the dowel to the vehicle, but that must extend less than 2.0 cm out in front.

- The voltage across any two points can not exceed 9v.

Additional Rules

- Must activate the vehicle for a run with an unsharpened #2 pencil moved vertically.

- Electronic and drive components can be used on vehicles, and can be made by contestants or bought

- The vehicle cannot be remotely controlled or tethered.

The definitive rules are located in the official rules manual. Know your rules front to back. You can never read the rules manual too many times.

Competitive scores for EV can come within fractions of a point at times, so fast and accurate is the winning combination.

Competition

- Distance given at competition will be from 9 to 12 meters, with intervals of 0.5m at Regionals, 0.1m at State, and 0.01m at Nationals.

- Vehicles are scored based on the following:

- Distance to the target point from the 1/4 inch dowel in cm

- Time in seconds measured between 0.5m and 8.5m

- Bonus = 0.2 * (110 - distance between cans to the nearest 0.1 cm)

Run Score = Run Time (sec) + Distance Score (cm) - Bonus + Penalties

Design

The basic chassis of an EV is fairly rigidly defined in the rules, and is actually fairly similar to Scrambler.

Speed

Like Scrambler, you have to worry about speed. Precision (repeatable performance) and accuracy (close results) are what a good vehicle aim for, but this alone will not do well. A combination of speed and precision/accuracy will win.

To achieve a high speed, you can do a few things:

- Use a fast motor

- Use different gears to change your ratio and turn your axle faster.

Electric motors inherently run at very high speeds with little torque. In addition, the greater the load placed on a motor, the slower it will run. So, without gearing, a vehicle would at best slowly accelerate up to a very high speed, and at worst, the motor will not have enough torque to get the vehicle moving.

Smaller, wider wheels are just a matter of convenience. A thin, large, flat wheel is more difficult to secure to a shaft and may cause wobbling.

gh likes to use pulleys from Small Parts with o-rings pulled over them. This kind of wheel is strong, very stable, and mounts to a a commonly used shaft size easily. In addition, the "tires" contact the ground in a single spot, allowing the lower sideways slip benefits of a thin wheel (as opposed to, say, fat foam wheels).

Many teams also opt to use wheels from BaneBots. [1]

Adjustment

Getting the vehicle to go straight is very important. For most people, this means building in a mechanism that allows them to change the angle between the axles, which changes the direction that the vehicle will curve towards.

Others choose a more complex setup -- their left and right wheels use independent motors, which are ran at different speeds to counteract any imperfections in the frame of the vehicle. This kind of correction might be a bit more susceptible to tilted floors, because it relies on a small amount of wheel slip to enact the turning.

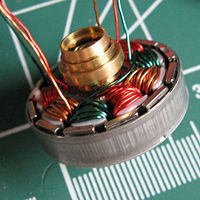

Motor Cogging

Pick up a bare motor (no gearboxes or gearheads) and turn the shaft. Do you feel how the shaft tries to "cog" to certain positions? This is caused by the poles of the rotor (for brushed motors) lining up with magnets in the stator, and is known technically as "detent." The same thing will happen on the vehicle, and the better and more powerful your motor is, the more prounounced the cogging action is. The distance traveled by your vehicle is quantized (separated into discrete values) by this cogging action. However, gear reduction and small wheels will minimize these effects. You can calculate the how much each "cog" of the motor will affect the distance traveled by the vehicle with this formula:

- [math]\displaystyle{ D = \frac{w\times\pi}{n{\times}r} }[/math]

Where:

- D = distance traveled with each "cog"

- w = wheel diameter

- n = number of "cogs" in each revolution of the motor shaft

- r = gearing (or pulley) ratio between the motor and the wheel

As you can see, this effect is only significant for those who are have bought bare motors and built their own (simple) low-ratio geardown system.

Some ways to minimize this:

- Use a higher geardown ratio

- Use smaller wheels

- Use a motor with lots more cogging angles, or one that is detent free (like some Hacker and Kontronik brushless motors that use slotless stators)

Braking

Since EV is more forgiving than Scrambler in terms of what you can use, you have many more options in choosing braking mechanisms.

Mechanical Braking

As mentioned later, mechanical braking mechanisms like wingnut systems and others carried over from Scrambler. These, for the most part, are used almost exclusively when the timing mechanism is mechanical as well.

Electrical & Electromagnetic Braking

You don't actually have to build a separate braking mechanism to stop your vehicle. If you have designed your drivetrain properly, the motor itself is sufficient to stop the vehicle.

Even if your vehicle uses a low-tech timer, you can still benefit from the rules by using an electrically triggered brake.

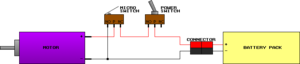

- Cutting power You can cut power to your vehicle using a simple circuit with a microswitch in series with the motor. In the wingnut system, the wingnut would not hit the frame as it would on a Scrambler, but instead hit the microswitch to stop the vehicle.

- Motor braking Lenz's law states that current generated in a loop by flux will oppose the flux that generated it. A simple application of Lenz's law can be seen in the eddy current brake. A simple eddy current brake can be easily made by connecting the two terminals of a DC motor. Now, the coils of magnet wire within the motor form a loop, and when turned, the moving magnets in the motor generate current within this loop. The motion is then counteracted by the force created by the current generated, by Lenz's law. And so, a motor begins to resist rotation when you connect its terminals together. In general, larger, more power, and more expensive motors tend to brake better this way. If you use a motor controller to control your motor, look in the documentation to see if it supports braking. Most that do will automatically connect the motor terminal together when a neutral signal is received. If your motor controller does not support it, or if you are not using a motor controller, it is trivial to use a relay or power transistor to connect the close the motor terminals when needed. In general, using the motor to brake is better than building a separate eddy current brake unless your motor is severely underpowered compared to your vehicle or if you vehicle has a lot of inertia.

- Keep in mind that the scheme described here is designed to convert motion into electric current, which is then immediately converted to heat. Do not be surprised if your motor or braking mechanism becomes very hot.

- Motor reversing Simply reversing the motor for about 100ms (your mileage may vary on how long) and then shutting off power will quickly stop a vehicle. This can then be combined with the motor braking to hold position.

- Like motor braking, quick motor reversing will generate lots of heat if you have a high-powered vehicle. If your motor uses NeFeB magnets, some of which have lower temperature ratings (most N50 magnets go to only 80 °C), make sure you do not exceed those ratings.

To summarize: an EV's motor can effectively serve as its braking system with a bit of simple circuitry. You do not need to build a separate braking system unless your vehicle is too heavy. Electromagnetic brakes can stop a vehicle without any mechanical parts touching, and generates more braking force for vehicles traveling faster.

Distance

The vehicle has to account for distance traveled in order to stop. There are three basic ways to do this.

Mechanical

See Scrambler braking systems. However, instead of just locking the wheels, you might consider using actuating a switch that cuts power to the motor(s) and maybe activates a braking system. See Dark Sabre's posts on microswitches.

Timer-based

This is fairly simple. The motor is turned on for an adjustable amount of time and then stopped. This can be done with a microcontroller or a one-shot 555 timer. With a microcontroller, this time can be very exact, down to the milli- or nanosecond by using a delay loop. The 555 timer can be adjusted by using a potentiometer for the R in the one-shot circuit.

Sensor-based

Because using sensors that sense the environment is not allowed by the rules, you are really limited to what types of sensors you can use. A shaft encoder counts revolutions of a shaft, in this case one of the axles of your car. By using a shaft encoder, you can figure out how far the car has traveled and based on that, stop the motors.

Time

The contestants must predict the time the vehicle will take to travel the given distance. The best way to know how long it will take is to run the vehicle at every distance multiple times and record the times.

Stopwatch Method

The simplest way to get the time of each run is to use a stopwatch. There are a couple of things to note about reaction time.

- Say your reaction time is about 0.3s consistently. Adding or subtracting three tenths of a second from you run's time won't make a huge difference in your score.

- The effect your reaction time has on your score is decreased even further by the fact that it should take you nearly the same amount of time to react to the car stopping. Say your 0.3s reaction time causes you to start the timer 0.3s after the car has started. It would also take you about 0.3s to stop the timer after the car has stopped. The time is just shifted 0.3s over, it starts later and ends later, but the time elapsed is still the same as the time it took for the car to travel the distance.

Microcontroller Timer Method

Another option, if you're using a microcontroller is to have a timer start right after the motor(s) are started and stop right after the motor(s) are stopped. Once the timer stops, the microcontroller would display the time on a display. tehkubix used a 7-segment LED to flash each digit in the time down to the hundredths of a second. If you can't add a 7-segment LED for whatever reason, you could use a single or multiple individual LEDs. This method requires more attention when reading the display because you may miss a flash. If using just one LED, the controller could flash the light once for each second elapsed in the time. Say the time was 16 seconds and 23ms. The light would flash once, pause for a few seconds, flash 6 times, pause, flash 2 times, pause and then 3 times.

Voltage Regulation

The 2017 rules specify that the voltage across any two points on the vehicle must not exceed 9v.

Batteries: Many teams opt to use NiMh or alkaline batteries.